| Home Contact Us | Phone: +1 (412) 810-2240 |

|

Industrial Sensors & Measurement

Systems For Control, Measurement & Management for Metal Mills, Process Automation, and Overhead Cranes. |

| MSE-HMD84 Digital Hot Metal Detector (HMD) Technical Info |

| Hot Metal Detectors | MSE-HMD84 | Description | Technical Info | Housing Info | Data Sheet | Request More Info |

|

The following is additional technical and operation information on the MSE-HMD84 Low Temperature Digital Hot Metal Detector |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

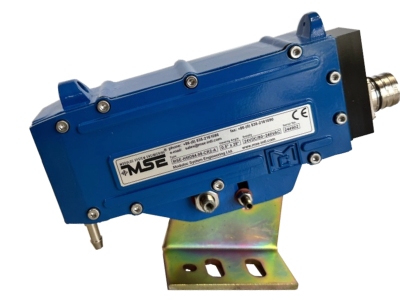

The self-contained MSE-HMD84 Low Temperature Digital Hot Metal Detector is available with either air coolant chamber venting as air purge or alternatively with a water coolant chamber and separate air purge. Shown mounted on a supplied MSE-LH-01 "L" Mounting Bracket. |

To accommodate variation in bar temperature and background IR, various precise threshold are programmable via covered switches from 160°C to 460°C ( 320°F to 860°F) for Steel and 200°C to 500°C ( 392°F to 932°F) to ensure reliable switching with reference to both the displayed background and product IR signal. Furthermore, response time is programmable from 1ms to 250ms to accommodate black spots on the bar. The MSE-HMD84 incorporates a remote self-check facility remotely energized by closed contacts that illuminates an internal IR LED to switch the detector and verify the' outputs are operating correctly. The MSE-HMD84 will operate from either 24VDC or optional 80-240 VAC power input. Standard outputs include a cradle relay, and both NPN/PNP transistor outputs. An optional fast reed relay with a 2ms response time is also available as an additional output. The MSE-HMD84 is a direct replacement for the MCSL Model MD8100-HG, MD8400, MD84100, and Model MD85100-HG Hot Metal Detectors. Please contact us for additional information.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Smallest Detectable Product when utilizing a 0.5° x 25° Lens |

Approximate Guideline for Temperature of Hot Product above Preset Threshold vs % of Vertical Field of View |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The table below identifies the minimum % of vertical field of view required with hot steel at stated temperature for it to be repetitively detected. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Lens Options MSE-HMD84 is shipped as standard with 0.5° x 25° FOV Slit Rectangular Lens. Optional rectangular and spot lenses are available, as listed in the table below, may be chosen to accommodate the monitoring of both large and small product at close proximity or substantial distance. Even product dramatically deviating about the center of Field of View can be monitored with a slit Field of View lens arrangement.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This interchangeability of lenses allows the user to adopt one standard sensor to suit individual installation requirements. Please contact us for other FOV lens requirements. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The MSE-HMD84 is a direct replacement for the MCSL Model MD8100-HG, MD8400, MD84100, and Model MD85100-HG Hot Metal Detectors. Please contact us for additional information. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Spot Lenses |

Rectangular Lenses |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hot Metal Detectors | MSE-HMD84 | Description | Technical Info | Housing Info | Data Sheet | Request More Info |